7 Best Packaging for Cannabis Flower

Cannabis packaged for sale should be conditioned to keep the buds as fresh as possible until opened by a consumer. Standard methods have been developed and refined over decades of cannabis cultivation and retail. However, despite the best efforts at preservation, market pressures often result in cannabis being sold before it is fully cured.

This might not bother many buyers looking forward to smoking or vaporizing their purchase right away; however, those buying premium flowers expect them to be appropriately dried and sealed from outside contamination first. The cannabis packaging used for this purpose needs to be functional and attractive without sacrificing too much quality.

What makes adequate packaging for cannabis flowers?

Packaging should do more than hold a cannabis product in place. Its design and construction should minimize the risk of damage or contamination from everyday use, whether at dispensaries or through mail-order services. Materials used for flower packaging need to be sturdy enough to protect an individual cannabis bud yet flexible enough to allow easy access when the package is opened. The material's thickness and opacity also impact its ability to block air and light penetration to ensure marijuana remains as fresh as possible between the time it is harvested and consumed by a consumer.

7 Best Cannabis Packaging Options

Let's take a look at different types of cannabis package design. We've seen what components our cannabis packaging should include, so let's look at how various sorts of packaging for cannabis leaves and flowers work.

1. Glass Jars

Strong glass jars are a simple but effective way to store dried cannabis. Jars accommodate the entire plant; however, resin glands on the exterior of the stem can sometimes be wiped off during transit or storage. An airtight lid ensures no moisture issues arise after packaging and will keep any odors from leaking out.

The problems with glass jars are that they are breakable and heavy. Minimizing the risk of breakage means using small containers that do not hold much cannabis, making them impractical for producers with large harvests. They must also be carefully stored away from moisture and light sources to avoid contamination by mold or fungus, which can damage flowers as quickly as other organic materials like food.

2. Plastic or Metal Tins

Tin cans are less breakable than glass but still not practical for mass production. They store just a few grams of cannabis and give off an unpleasant metallic taste when opened. Plastic bags offer slightly more protection from outside moisture, air, and light sources but do nothing to keep the product fresh once it is unsealed.

Small, plastic containers are often used for cannabis packaging samples in dispensaries. They have the added benefit of being microwavable to quickly heat up or vaporize concentrates without using an external heating device. While these small containers are practical, they are not very durable. Metal tins are more protective than mylar bags but still unreliable for anything other than small amounts of flower because they don't keep out water vapor and are harder to reseal after opening.

3. Tin Cans (with Child Resistant Lid)

A tin can with a child-resistant lid is about as heavy-duty as packaging comes before moving into the realm of professional retail display units. These metal cans seal tightly enough to prevent moisture or air penetration even during rough handling or shipping.

However, a tin can is not attractive or discreet enough for retail sales, making it unsuitable even if it will keep the product fresh on store shelves. In addition, metal cans are bulky and hard to transport, limiting their use to wholesale distribution only.

4. Child-Resistant Bags & Exit Bags

Child-resistant bags are made of plastic or laminated paper and can come in several colors. They offer the most flexibility in size but do not provide any protection against moisture or oxygen contamination. A cannabis product stored inside a bag will not spoil quickly, but it is more likely to lose its flavor, making the flowers less appealing to consumers.

5. Plastic Zipper Bags

With zippers that close securely, these bags allow the consumer to reseal them after opening for freshness. The downsides of using plastic zipper bags are that they are bulky and cannot be microwaved for fast-acting dried cannabis products like pre-rolled joints.

6. Plastic Collapsible Bags

If produced on a large scale, collapsible plastic bags could become standard packaging for pre-rolled joints. These bags are slightly more expensive to produce than laminated paper but store flat when not in use, making them easier to transport and store than plastic zipper bags.

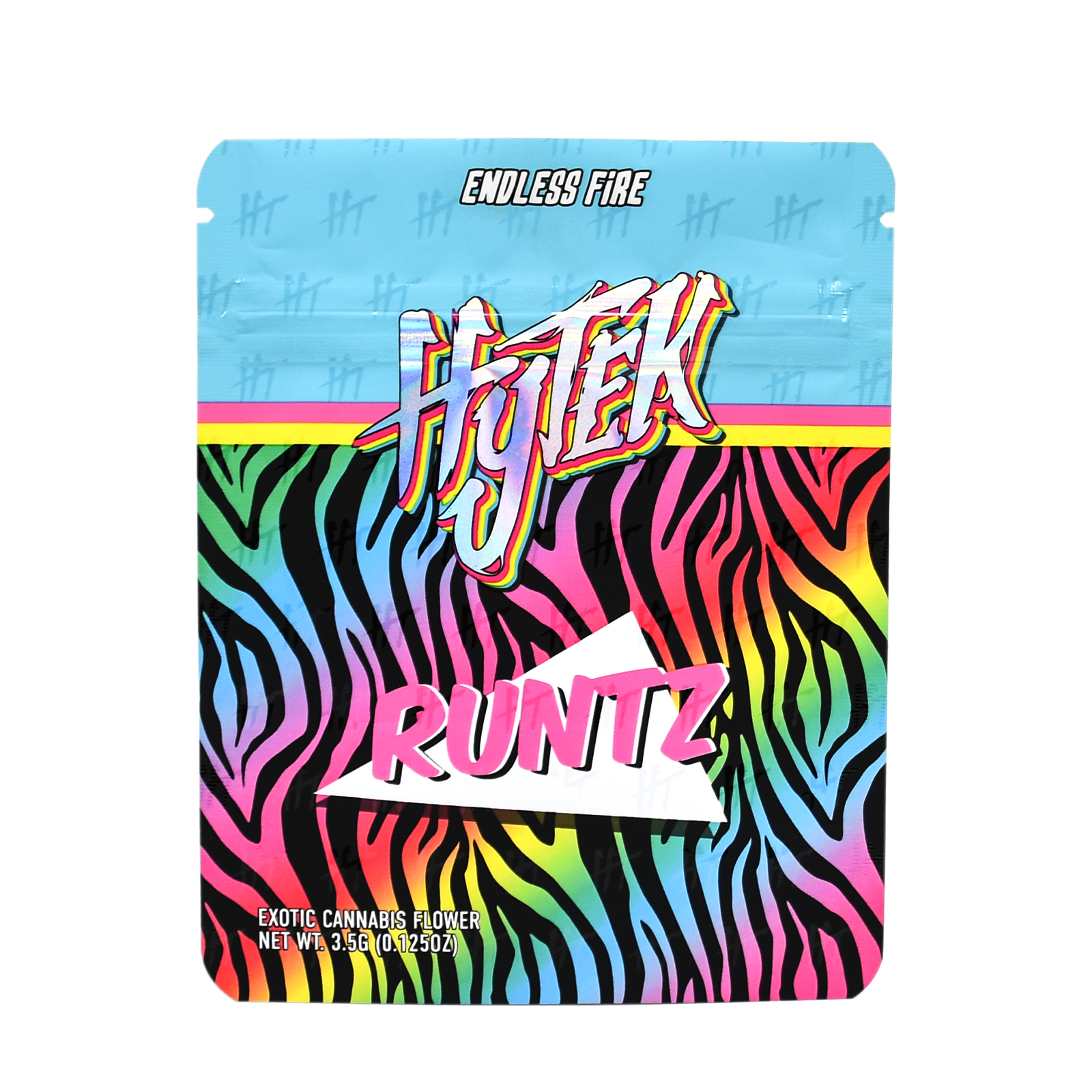

7. Plastic Laminated Paper Bags

The most popular and economical type of packaging for flowers is a plastic laminated paper bag, a durable pouch made of three layers. The inside layer that contacts the flower is usually food-grade polypropylene or another moisture barrier that doesn't transfer flavor when in contact with cannabis concentrates. The exterior is often PVC, which offers greater strength and security from water vapor penetration. A clear label window allows growers to add branding without cluttering up the look of the package itself.

One downside is that these bags are not microwaveable; however, they keep out light and moisture better than any other retail-ready option available on a large scale in legal markets. In addition, they come in various sizes for different weights of marijuana depending on the regulations of the particular state or country of sale.

Final Words

Packaging for cannabis flowers should be the most durable material possible without sacrificing discreetness, usability, and recyclability. For example, a bag offers durability but lacks the self-standing capability or microwavable technology; a metal tin can is attractive but cannot be used for anything other than wholesale distribution and has no added value in retail settings; plastic laminated paper bags offer microwavable heating options and easy transportation while still maintaining the least amount of environmental impact.

With this said, manufacturers should keep in mind that any packaging which comes in contact with cannabinoids like THC must be 100 percent free from contamination by external elements such as pesticides or mold.

To learn more, call (800) 674-9488 or email info@greentechpackaging.com